Product Overview

Advanced structural porcelains, as a result of their unique crystal structure and chemical bond attributes, show performance benefits that steels and polymer materials can not match in extreme settings. Alumina (Al ₂ O TWO), zirconium oxide (ZrO TWO), silicon carbide (SiC) and silicon nitride (Si four N FOUR) are the 4 major mainstream design porcelains, and there are necessary differences in their microstructures: Al ₂ O ₃ belongs to the hexagonal crystal system and depends on strong ionic bonds; ZrO ₂ has 3 crystal forms: monoclinic (m), tetragonal (t) and cubic (c), and gets unique mechanical residential properties with stage adjustment toughening mechanism; SiC and Si Five N four are non-oxide ceramics with covalent bonds as the major part, and have more powerful chemical stability. These architectural differences straight result in substantial differences in the prep work procedure, physical homes and design applications of the four. This article will methodically assess the preparation-structure-performance relationship of these 4 ceramics from the viewpoint of materials science, and explore their leads for commercial application.

(Alumina Ceramic)

Preparation process and microstructure control

In terms of preparation procedure, the four ceramics reveal noticeable differences in technological courses. Alumina ceramics use a relatively conventional sintering procedure, generally using α-Al ₂ O six powder with a pureness of greater than 99.5%, and sintering at 1600-1800 ° C after completely dry pressing. The secret to its microstructure control is to inhibit unusual grain growth, and 0.1-0.5 wt% MgO is normally added as a grain limit diffusion prevention. Zirconia porcelains require to present stabilizers such as 3mol% Y ₂ O ₃ to retain the metastable tetragonal phase (t-ZrO ₂), and use low-temperature sintering at 1450-1550 ° C to stay clear of extreme grain growth. The core process obstacle depends on accurately managing the t → m stage change temperature home window (Ms factor). Given that silicon carbide has a covalent bond proportion of as much as 88%, solid-state sintering calls for a heat of greater than 2100 ° C and depends on sintering help such as B-C-Al to form a liquid phase. The response sintering method (RBSC) can attain densification at 1400 ° C by penetrating Si+C preforms with silicon thaw, however 5-15% free Si will remain. The prep work of silicon nitride is the most intricate, normally making use of general practitioner (gas stress sintering) or HIP (warm isostatic pushing) processes, adding Y TWO O TWO-Al ₂ O ₃ series sintering aids to form an intercrystalline glass phase, and warmth treatment after sintering to crystallize the glass phase can dramatically boost high-temperature efficiency.

( Zirconia Ceramic)

Contrast of mechanical buildings and strengthening system

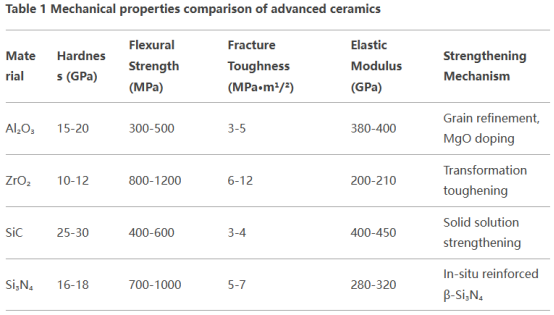

Mechanical residential properties are the core analysis indicators of architectural ceramics. The 4 types of products reveal entirely various strengthening mechanisms:

( Mechanical properties comparison of advanced ceramics)

Alumina mainly depends on fine grain fortifying. When the grain size is reduced from 10μm to 1μm, the strength can be increased by 2-3 times. The outstanding strength of zirconia comes from the stress-induced stage transformation device. The anxiety field at the crack tip triggers the t → m stage improvement gone along with by a 4% volume development, resulting in a compressive stress shielding impact. Silicon carbide can boost the grain boundary bonding stamina via strong solution of components such as Al-N-B, while the rod-shaped β-Si five N four grains of silicon nitride can generate a pull-out effect comparable to fiber toughening. Break deflection and connecting contribute to the improvement of sturdiness. It is worth noting that by constructing multiphase porcelains such as ZrO TWO-Si Five N Four or SiC-Al ₂ O ₃, a selection of strengthening systems can be collaborated to make KIC exceed 15MPa · m ONE/ ².

Thermophysical residential properties and high-temperature behavior

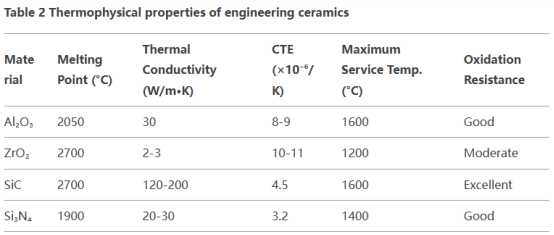

High-temperature security is the vital advantage of structural porcelains that differentiates them from traditional materials:

(Thermophysical properties of engineering ceramics)

Silicon carbide shows the best thermal monitoring efficiency, with a thermal conductivity of as much as 170W/m · K(similar to light weight aluminum alloy), which is because of its basic Si-C tetrahedral structure and high phonon proliferation rate. The reduced thermal growth coefficient of silicon nitride (3.2 × 10 ⁻⁶/ K) makes it have excellent thermal shock resistance, and the important ΔT worth can reach 800 ° C, which is especially suitable for duplicated thermal cycling atmospheres. Although zirconium oxide has the highest melting point, the softening of the grain boundary glass phase at high temperature will cause a sharp drop in stamina. By adopting nano-composite innovation, it can be raised to 1500 ° C and still preserve 500MPa strength. Alumina will certainly experience grain limit slide over 1000 ° C, and the enhancement of nano ZrO ₂ can form a pinning impact to prevent high-temperature creep.

Chemical stability and corrosion behavior

In a corrosive atmosphere, the 4 types of porcelains exhibit significantly various failure devices. Alumina will liquify externally in solid acid (pH <2) and strong alkali (pH > 12) services, and the corrosion rate increases exponentially with raising temperature, reaching 1mm/year in boiling concentrated hydrochloric acid. Zirconia has excellent tolerance to not natural acids, but will certainly go through low temperature degradation (LTD) in water vapor settings over 300 ° C, and the t → m stage transition will certainly cause the formation of a tiny split network. The SiO ₂ safety layer formed on the surface of silicon carbide offers it exceptional oxidation resistance below 1200 ° C, but soluble silicates will certainly be created in liquified antacids metal settings. The corrosion habits of silicon nitride is anisotropic, and the deterioration price along the c-axis is 3-5 times that of the a-axis. NH Two and Si(OH)₄ will certainly be produced in high-temperature and high-pressure water vapor, bring about product cleavage. By enhancing the composition, such as preparing O’-SiAlON porcelains, the alkali corrosion resistance can be raised by greater than 10 times.

( Silicon Carbide Disc)

Typical Design Applications and Instance Studies

In the aerospace area, NASA makes use of reaction-sintered SiC for the leading side parts of the X-43A hypersonic aircraft, which can stand up to 1700 ° C aerodynamic heating. GE Aviation uses HIP-Si six N ₄ to make generator rotor blades, which is 60% lighter than nickel-based alloys and permits greater operating temperature levels. In the clinical area, the fracture stamina of 3Y-TZP zirconia all-ceramic crowns has actually reached 1400MPa, and the service life can be reached more than 15 years via surface area gradient nano-processing. In the semiconductor industry, high-purity Al two O three porcelains (99.99%) are used as dental caries products for wafer etching equipment, and the plasma corrosion rate is <0.1μm/hour. The SiC-Al₂O₃ composite armor developed by Kyocera in Japan can achieve a V50 ballistic limit of 1800m/s, which is 30% thinner than traditional Al₂O₃ armor.

Technical challenges and development trends

The main technical bottlenecks currently faced include: long-term aging of zirconia (strength decay of 30-50% after 10 years), sintering deformation control of large-size SiC ceramics (warpage of > 500mm parts < 0.1 mm ), and high production expense of silicon nitride(aerospace-grade HIP-Si two N ₄ reaches $ 2000/kg). The frontier growth instructions are focused on: 1st Bionic framework design(such as shell split structure to boost toughness by 5 times); ② Ultra-high temperature sintering innovation( such as trigger plasma sintering can achieve densification within 10 minutes); six Intelligent self-healing porcelains (containing low-temperature eutectic stage can self-heal fractures at 800 ° C); ④ Additive manufacturing modern technology (photocuring 3D printing accuracy has reached ± 25μm).

( Silicon Nitride Ceramics Tube)

Future growth patterns

In a thorough comparison, alumina will certainly still control the typical ceramic market with its cost advantage, zirconia is irreplaceable in the biomedical field, silicon carbide is the favored material for severe environments, and silicon nitride has terrific possible in the area of high-end devices. In the following 5-10 years, through the integration of multi-scale structural policy and smart manufacturing innovation, the efficiency limits of design porcelains are expected to attain new breakthroughs: for example, the design of nano-layered SiC/C porcelains can attain durability of 15MPa · m ONE/ TWO, and the thermal conductivity of graphene-modified Al ₂ O ₃ can be raised to 65W/m · K. With the improvement of the “dual carbon” strategy, the application scale of these high-performance porcelains in new power (gas cell diaphragms, hydrogen storage space materials), environment-friendly production (wear-resistant components life raised by 3-5 times) and various other fields is anticipated to keep an ordinary annual growth rate of greater than 12%.

Supplier

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested in aluminum nitride thermal pad, please feel free to contact us.(nanotrun@yahoo.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us